- THE PROCESS

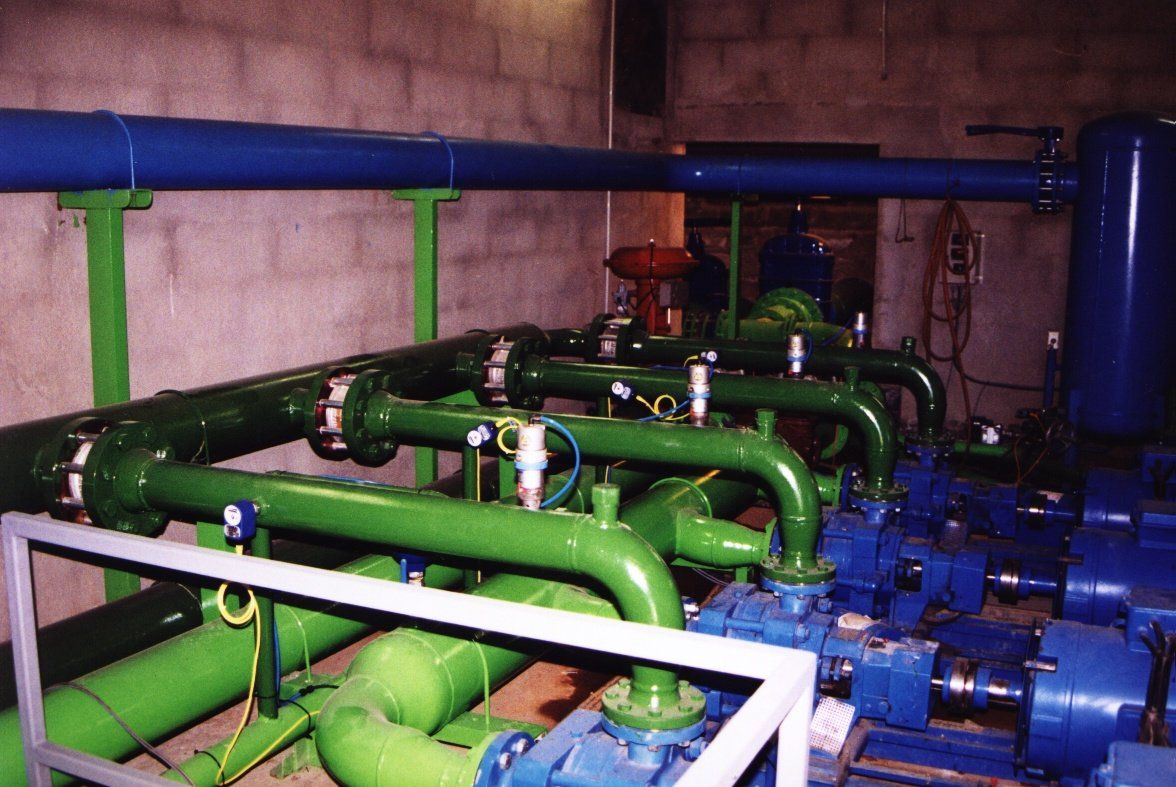

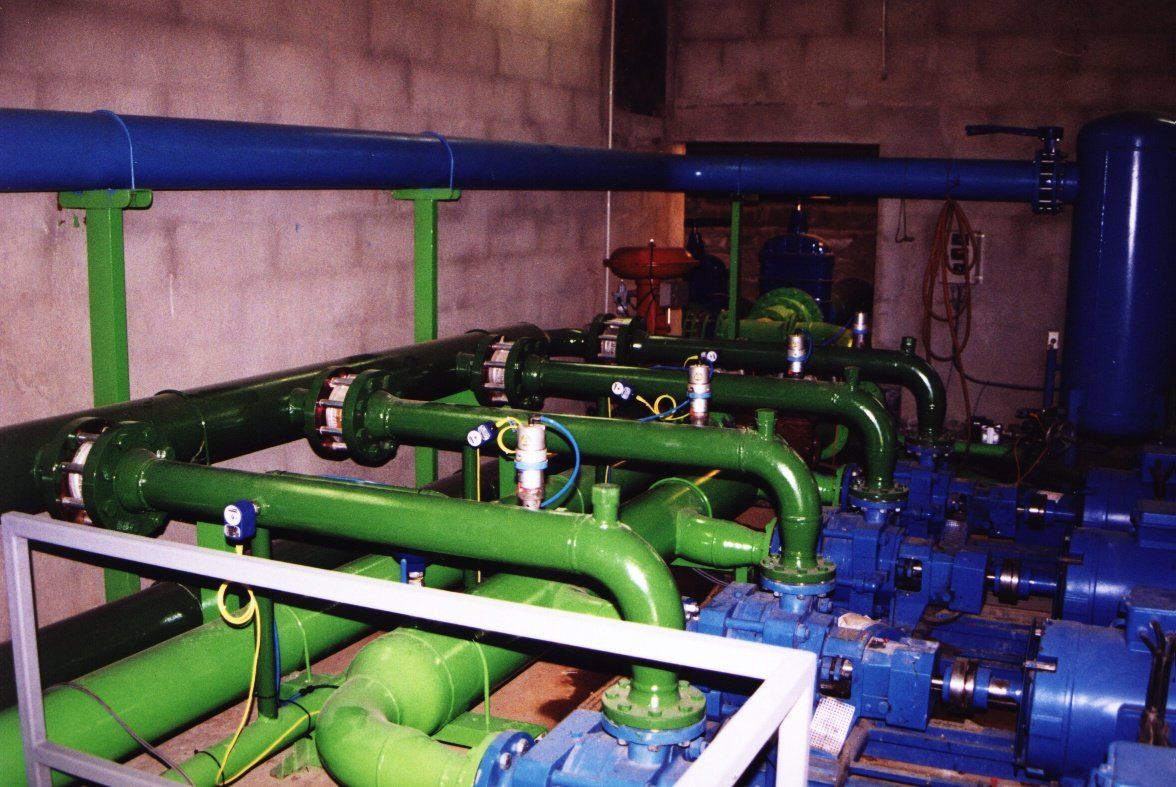

- PRESSURE APPARATUS

- ASSEMBLY

- RESOURCES FOR EXTERIOR ASSEMBLY

- 1. Approach

- 2. Installation

- 3. Legal processing

- 4. Official inspections

We plan the work spaces, study the optimal option for the client and calculate and size the pipes.

We implement the installation and necessary equipment. We carry out the commissioning.

We verify and approve the installation.

We carry out official periodic inspections according to regulations, we have an after-sales service.

- Facilities

- Boilermaking

Paintable steel tube with welded fittings

Pressed/welded stainless steel tube with accessories

Galvanized steel pipe and threaded fittings

Aluminum tube with screwed accessories included

Stainless steel containers and assemblies

MAIN SECTORS

INDUSTRIAL

CHEMI-PHARMA

FOOD

ENVIRONMENTAL

Assistance to Construction Companies, Engineering Companies and Finalist Industry

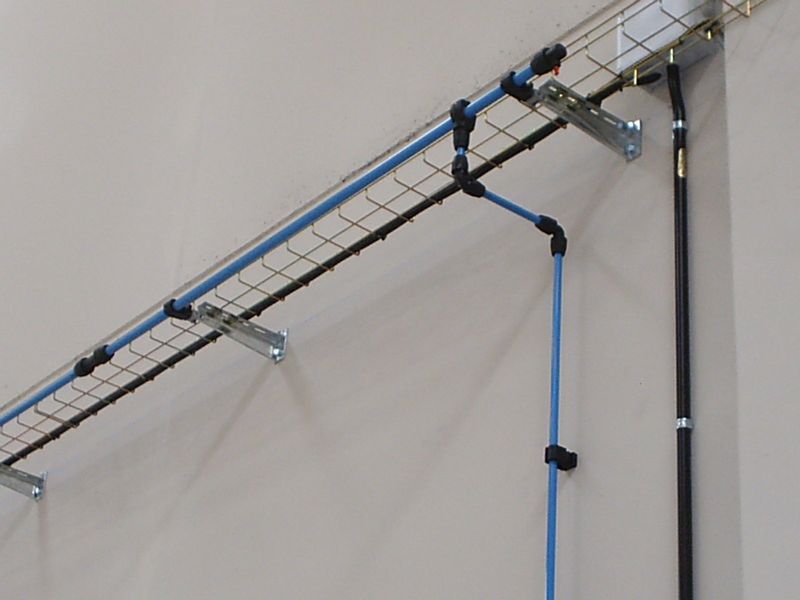

Compressed air

- Modular applications in aluminum tube.

- Painted iron pipes with welded joints.

- Galvanized steel pipes with threaded joints.

- Stainless steel assemblies (welded and pressed).

Water

- Pumping large flows.

- Welders and approved procedures.

- Pipe threading lathes up to 4″.

- Threaders up to 4″.

- Portable electronic soldering irons.

- Drilling machines, colliers and tools for portable use.

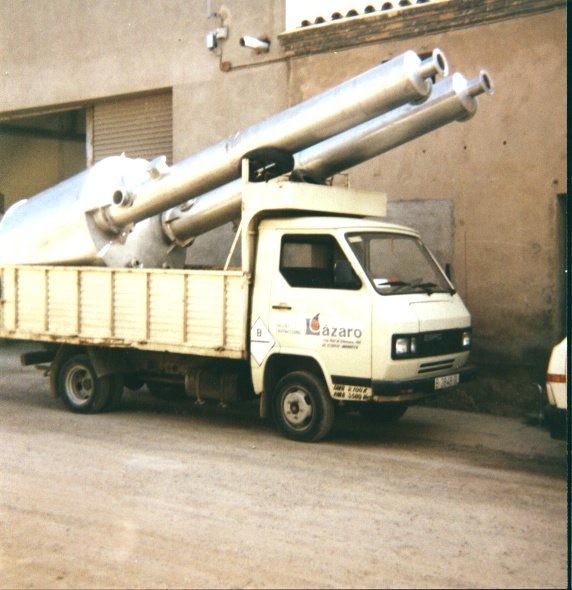

- Own means of transportation and lifting.